| Building, Construction And Industrial Roofing Division |

| Product |

Image |

Description |

Application Area |

|

|

|

| Self-adhesive Bitumen Membrane |

|

This product is a self-adhesive membrane containing rubber. It is excellent in blocking water, air and noise. It is non-curing and has excellent elasticity, which helps reduce the noise more effectively. Self-adhesive bitumen membrane is an extraordinary coiled material for roofing because it is cost-effective and easy to apply, and it has excellent performance in terms of waterproofing and insulation. Its Shelf life is 12 months when stored in a cool and dry place within its original packaging. |

It is widely used in roofing, flooring and sound insulation.. Making sure all surfaces are clean, dry and free of any loose impediments before removing the backing paper or film and then apply to the other surface and compact to form the seal.

Product dimensions:

1.2mmx1mx20m;

1.5mmx1mx20m;

2.0mmx1mx15m. |

|

|

|

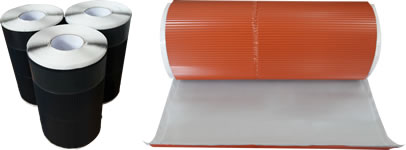

| TPO Self-adhesive Membrane TPO |

|

TPO is the abbreviation of the word ‘thermoplastic polyolefin’. It is an excellent environmentally friendly product with a long service life. TPO has the advantages of PVC, being weather and cold resistant. Additionally, TPO, like EPDM performs well under high temperatures. Therefore, it has good mechanical properties, excellent workability, and high toughness. Its Shelf life is 12 months when in a cool and dry place with original package. |

TPO is widely used in roofing and flooring. Making sure all surfaces are clean, dry and free of any loose impediments before removing the backing paper or film and then apply to the other surface and compact to form the seal.

Product dimensions:

1.2mmx2mx20m;

1.5mmx2mx20m;

1.7mmx2mx20m. |

|

|

|

| EPDM Waterproofing Membrane EPDM |

|

EPDM waterproofing membrane is made of EPDM rubber which has excellent performance amongst polymer waterproof materials. It excels at avoiding separation and crack in regular building movement. EPDM performs well in all weather conditions and has good UV and corrosion resistance because of its dimensional stability and durability. Moreover, TOP BEST - EPDM Waterproofing Membrane has high tensile strength and elongation properties, is easy to use, does not pollute, has a strong puncture resistance and has a service life of 50 years.

Its Shelf life is 12 months when stored in a cool and dry place with original package. |

TOP BEST - EPDM Waterproofing Membrane is used for waterproofing in roofing, basements, bathrooms, industrial and civil buildings, as geosynthetic pads used in swimming pools as well as channel and irrigation systems. It is especially suitable for projects requiring high performance on durability, anti-corrosion and distortion prevention.

Product dimensions:

1.2mmx1.2mx20m;

1.5mmx1.2mx20m;

2.0mmx1.2mx20m. |

|

|

|

| TP-653 Polyurethane Sealant |

|

Top Best 653 is a one-part polyurethane sealant, which cures to form a permanent watertight seal. 653 allows movement and will not damage metal coatings. It can be applied to a wide range of materials and can be coated repeatedly. |

Provides a flexible waterproof seal and can be used for sealing a blade’s root at its inside track’s gaps, and also the glass fiber-reinforced plastics at their lapping joints

. It is also ideal for vibration and noise reduction in industrial applications, sealing joints in caravans and motor homes, sealing movement joints in concrete floors, bedding sealing of flashings in industrial buildings.

Available in cartridge and sausage format and is applied using sealant or sausage guns. |

|

|

|

| TP-Silicon Sealant |

|

Top Best General Purpose Silicone Sealant bonds to most surfaces in construction and glazing. It is suitable for both interior and exterior use. It has excellent ageing resistance and cures to form a long lasting seal. |

Top Best Silicone Sealant is ideal for sealing joints in many applications. It has excellent adhesion to most surfaces, including metals, glass and plastic. |

|

|

|

| TP-702 Insulating Glass Hot Melt Butyl Rubber |

|

Top Best 702 is a hot melt butyl rubber, specifically designed for the first seal in insulating glass. It has high airtightness, anti-moisture properties and excellent UV resistance. Remains flexible throughout its service life without losing tack. |

All surfaces should be clean, dry, free from grease and loose impediments. Apply the sealant from the drum with the special hot-melt extrusion pump, adjusting the pressure of the pump according to the ambient temperature in order to control the sealants diameter. Complete the double sealing with silicone sealant, polysulphide sealant. The extrusion temperature should be in the range 120°C to 140°C and should be applied where the environmental temperature is greater than 8°C. |

|

|

|

| TP-651 Bath Trim For Water Tanks & Wet rooms |

|

Top Best 651 Bath Trim is a high quality plastic extrusion, which has high quality butyl tape applied to one side. This product is designed to adhere to ceramic tiles, baths and showers. The product provides a waterproof seal and is very conformable with a smooth wipe-clean surface. |

The bath Trim is hinged in the centre and can be used to seal around the bath, sink and accessories in the bath or wetrooms. Cut a strip to the desired length for the seal, fold along the hinge, remove the release film in short lengths and apply pressure to the tape to form a tight seal to the joint. For corners cut a triangle at an angle of 45° at the end where the join is to go. Once all the bath trim is in place push hard along the whole length to ensure good adhesion. |

|

|

|

| TP-656B Single-sided Waterproof Tape |

|

Top Best 656B is a self-adhesive waterproof sealant which has strong adhesion and can stick to most substrates. It remains flexible throughout its service life and is easy to apply. As well as providing a water tight seal the tape has good anti corrosion and UV performance properties with a life span up to 20 years. |

All surfaces should be clean, dry, free from grease and loose impediments. Application areas include the joint area between coloured steel plate and sun panel, drainage systems, joint areas between windows and doors, concrete roofs and piping systems. Remove the release paper, apply the tape along the joint and using hand or roller pressure push the aluminium foil firmly to seal across the joint. |

|

|

|

| TP-656A Aluminum Flashing Tape |

|

Top Best 656A is a butyl sealant tape with beige coloured aluminium to provide an attractive appearance. The product has excellent weather resistant properties and is easy to install. This butyl rubber tape remains flexible throughout its service life and has a life span up to 20 years. |

This tape can be applied to roof flashing systems, sloped roof window flashing systems, installed solar panel flashing systems and other integrated flashing installations. The tape is applied with the flashing system components of the roof or the roof system peripherals and pressing firmly to achieve the seal. |

|

|

|

| TP-666 Steel Structure Butyl Sealant |

|

Top Best 666 is a neutral sealant with excellent properties of water resistance, anti-aging, anti-corrosive and flexibility under high and low temperature environments. Synthetic rubber non-setting bedding sealant. |

Can be used for general sealing in roofing and cladding where a thin joint is required and for sealing seams, for example in flashings. Excellent for bedding aluminium window frames and general bedding and joint sealing in caravans. Can be applied by using a cartridge sealant gun or with a sealant pump when using the drum sealant. |

|

|

|

| TP-660 Waterproof Butyl Tape |

|

Top Best 660 tape is ideal for use in roofing and industrial applications. It remains flexible throughout its service life and is designed to accommodate movement. The tape has a high weather resistant performance, is anti corrosive, protects against UV and has a life span up to 20 years. |

All surfaces should be clean, dry, free from grease and loose impediments. Used in steel and aluminium roofing systems and is an ideal membrane tape for sealing joints against air, gas and water. Remove backing paper and position the overlapping surface to the sealant before applying pressure to seal across the joint. |

|