| Wind Power Products Division |

| Product |

Image |

Description |

Application Area |

|

|

|

| 665 Vacuum Bag Tape (Room Temperature) |

|

Top Best 665 has high surface adhesion on vacuum bag and a variety of tools. This is a cost effective tape. In the curing cycle it has excellent seal and is very easy to remove from the surface after curing. |

All surfaces should be free from dust, grease, oil, loose mortar and any other foreign materials. Application areas are between vacuum bags or between vacuum bag and composite tools. Apply direct onto the surface and press sufficiently along its whole length to achieve good initial adhesion before removing the backing paper to offer other surface to the tape and push firmly across the joint. It is suitable for curing under room temperature to 120°C. |

|

|

|

| 661 Vacuum Bag Tape (Middle Temperature) |

|

Top Best 661 has high surface adhesion on vacuum bag and a variety of tools. In the curing cycle it has excellent seal and is very easy to remove from the cold or heated surface after curing. |

All surfaces should be free from dust, grease, oil, loose mortar and any other foreign materials. Application areas are between vacuum bags or between vacuum bag and composite tools. Apply direct onto the surface and press sufficiently along its whole length to achieve good initial adhesion before removing the backing paper to offer other surface to the tape and push firmly across the joint. It is suitable for curing under room temperature to 150°C. |

|

|

|

| 662 Vacuum Bag Tape (High Temperature) |

|

Top Best 662 is based on advanced technology and has high surface adhesion on vacuum bag and a variety of tools. In the curing cycle it has excellent seal and is very easy to remove from the cold or heated surface after curing. |

All surfaces should be free from dust, grease, oil, loose mortar and any other foreign materials. Application areas are between vacuum bags or between vacuum bag and composite tools. Apply direct onto the surface and press sufficiently along its whole length to achieve good initial adhesion before removing the backing paper to offer other surface to the tape and push firmly across the joint. It is suitable for curing under room temperature to 204°C. |

|

|

|

| Top Best 653 Polyurethane Sealant |

|

Provides a flexible waterproof seal and can be used for sealing a balde’s root at its inside track’s gaps, and also the glass fiber-reinforced plastics at their lapping joints

It is also ideal for vibration and noise reduction in industrial applications, sealing joints in caravans and motor homes, sealing movement joints in concrete floors, bedding sealing of flashings in industrial buildings.

Available in cartridge and sausage format and is applied using sealant or sausage guns. |

Provides a flexible waterproof seal and can be used for airproofing and bonding a range of materials. It is ideal for vibration and noise reduction in industrial applications, sealing joints in caravans and motor homes, sealing movement joints in concrete floors, bedding sealing of flashings in industrial buildings.

Available in cartridge and sausage format and is applied using sealant or sausage guns. |

|

|

|

| Barrel Bolt Protection Tape |

|

Top Best Barrel Bolt Protection Tape is a self-adhesive waterproof sealant which has strong adhesion and can stick to most substrates. It remains flexible throughout its service life and is easy to apply. As well as providing a water tight seal the tape has good anti corrosion and UV performance properties with a life span up to 20 years. |

It is used for the protection of the barrel bolt of the blades. Other application areas include the joint area between coloured steel plate and sun panel, drainage systems, joint areas between windows and doors, concrete roofs and piping systems.

Usage: Remove the release paper; apply the tape along the joint and using hand or roller pressure push the aluminium foil firmly to seal across the joint. |

|

|

|

| Infusion Media |

|

This product is an extruded polypropylene mesh.

· Highest temperature 140°C.

· Wire diameter 0.3 ± 0.1mm.

· Pore diameter 1.0 ± 0.2mm.

·Weight 160 g/m2.

·Thickness 1.0 ± 0.2mm.

· Width ≤ 4m.

·Tailored length.

·Resin loss 0.7 ± 0.1kg/m2. |

This product is used as a ‘flow media’ to assist the flow of resin into a laminate during the resin infusion process. |

|

|

|

| Quick Infusion Media |

|

Quick infusion media is a moderate-cost and is designed to facilitate resin flow that is quick, controlled and predictable for resin infusion projects.

·PE Material.

· 3 dimensional grid like.

·Temperature 120 ° C.

·Weight 230 g/m2.

·Thickness 1.0 ± 0.2mm.

·Width 1.2m.

·Length 50m.

·Colour is green. |

It is widely used in vacuum infusion moulding processes. |

|

|

|

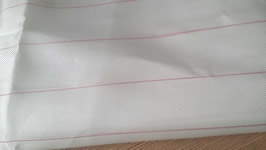

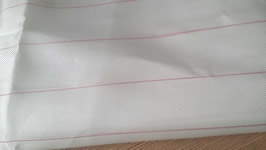

| Peel Ply |

|

Peel ply is a nylon base woven fabric with a red trace line. Peel plies are placed against the surface or the laminate where rough surface is required, which absorbs the excess resin during curing leaving the rough impression on the surface.

·Max temperature 190 °C.

·Material PA66

·Width 0.1 – 1.8m.

·Length 200m.

·Weight 85 g/m2.

·Tensile strength > 280 N/M. |

It is used to ensure a clean and non contaminated surface for secondary bonding or painting. Peel ply is heat set, scoured, traceable and has excellent release properties. |

|

|

|

| Vacuum Bag Film |

|

This product is a clear heat stabilised modified nylon resin vacuum bag film.

·Max width 14M.

·Translucent.

·To temperature of 120°C.

·Shrinkage <=2%.

·Density = 1.

·Tensile Strength > 40MPA.

·Thickness 50/65/75 μ m.

·Tailored length.

·Elongation >300% |

It is widely used in wind power, ship building and tank forming. High quality film used as part of the process to extract moisture, solvents and volatiles from curing composite. |

|

|

|

| Release Film (Perforated) |

|

Perforated release films are available in blue or red. They have evenly spaced holes that allow controlled removal of excess resin when vacuum bagging.

·Pore diameter 0.8mm ± 0.2mm.

·Pitch 8mm ± 0.1mm.

·Thickness 30 μ.

·Max working temperature 125 °C.

·Tensile strength >25MPA.

·Elongation >200%.

·Tailored length. |

It is often used as the first barrier between the composite laminate and the rest of the vacuum bagging materials. |

|

|

|

| Breather & Bleeder Felt |

|

Top Best DL51 is a non woven breather and bleeder felt made of polyester fibres. The material is chemical and temperature resistant.

· Weight 150 – 300 g/m2.

·Melting temperature 255-260 °C.

·Max temperature <205 ° C.

·Thickness 2mm – 5mm.

·Width 1.5M.

·Length 100m. |

Used as breather/bleeder cloth in vacuum bagging and as a release fabric in prepreg manufacture. The material is chemical and temperature resistant, is designed to discharge air bubbles and absorb excess resins. |

|

|

|

| PE Pipe |

|

·Temperature to 120 °C.

·Various diameter sizes from 6mm.

·Available in various lengths. |

PE Pipe is a general purpose vacuum hose for use in a wide range of vacuum composites applications.

This low priced hose is suitable for use as the resin feed and vacuum connection lines for resin infusion. |

|

|

|

| Spiral Pipe |

|

Spiral pipe is a spiral wound plastic tube which allows very easy flow of resin from the resin feed tube into and around a resin infusion project.

·Temperature to 120 °C.

·Diameter 10mm.

·Available in various lengths. |

Spiral piping is typically positioned underneath the feed line directing resin flow into the further corners of the part. |

|

|

|

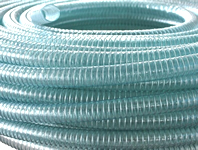

| PVC Steel Spiral Pipe |

|

This hose has steel wire incorporated within the wall gives reinforcement of the flexible PVC tubing. It provides excellent visual flow characteristics, which allow easy detection of blocks and air locks & hence. It is light weight, abrasion resistant and easy to handle.

·Inner diameter 16mm, 20mm, 25mm.

·Thickness 3mm.

·Temperature 130 ° C.

·Length 50m.

·Pressure value to 100 KPA. |

This hose is widely accepted by the composite industry especially for vacuum applications and resin transfer. |

|